Modern construction faces increasing demands for materials that withstand extreme environmental conditions while maintaining structural integrity. The growing concern over traditional steel reinforcement’s vulnerability to corrosion has led engineers and researchers to explore alternative solutions. Construction materials must endure diverse environmental stresses throughout their service life. Temperature fluctuations, freeze-thaw cycles, moisture exposure, and chemical attacks pose significant challenges to structural integrity. The factors become especially critical in infrastructure projects exposed to harsh weather.

Temperature performance

High-temperature exposure presents unique challenges for reinforcement materials. Under extreme heat conditions, materials must maintain their mechanical properties while resisting thermal expansion and potential softening. Conversely, cold temperatures test material brittleness and resistance to thermal contraction. Research has shown remarkable stability in mechanical properties across wide temperature ranges, indicating strong potential for diverse applications.

Freeze-thaw resistance

In regions experiencing frequent temperature fluctuations around the freezing point, materials undergo repeated expansion and contraction cycles. The durability of reinforcement materials becomes particularly critical in these conditions, as the constant volume changes lead to material fatigue and deterioration. Advanced testing protocols have demonstrated exceptional resilience under these demanding circumstances, maintaining structural integrity even after hundreds of cycles.

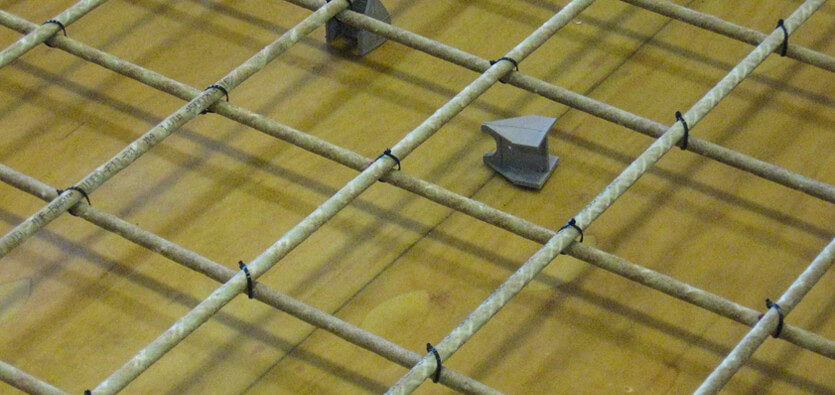

The GFRP Bars retain their structural properties after many freeze-thaw cycles under extreme weather conditions. Their non-metallic composition eliminates concerns about rust formation and subsequent concrete spalling, while their thermal compatibility with concrete ensures stable performance across temperature ranges.

Moisture and chemical exposure

Extended exposure to moisture represents a significant challenge for construction materials, particularly in coastal environments where salt spray adds another dimension of complexity. The resistance to chemical penetration becomes crucial in these settings, as it directly impacts the material’s long-term durability and structural integrity. Scientific studies have consistently shown superior performance in these challenging environments.

Laboratory testing results

Controlled testing environments have provided valuable insights into performance capabilities. These studies reveal minimal strength degradation after prolonged exposure to various environmental conditions while maintaining consistent elastic modulus across temperature ranges. The results demonstrate remarkable stability in structural properties, even under accelerated ageing conditions designed to simulate decades of environmental exposure.

Field performance data

Real-world applications have validated laboratory findings, providing crucial evidence of long-term performance reliability. Bridge structures in cold regions show excellent durability, while marine applications report minimal degradation over extended periods. These practical examples offer compelling evidence of the material’s capability to withstand diverse environmental challenges.

Impact of design considerations

Successful implementation requires careful attention to design parameters that account for environmental exposure. Engineers must consider thermal expansion coefficients, load distribution patterns, and service life requirements when developing specifications. This comprehensive approach ensures optimal performance across varying conditions and applications.

Ensuring optimal performance requires a systematic approach to quality control and maintenance. Regular inspections and performance monitoring help identify potential issues before they become significant problems. This proactive approach to maintenance has proven highly effective in maximizing service life and maintaining structural integrity.

Future development potential

Ongoing research continues to enhance material capabilities through advanced manufacturing techniques and improved resin systems. These developments promise even greater resistance to environmental stresses and expanded application possibilities. The construction industry’s growing understanding of these materials drives continuous improvement in both products and implementation methods.

Well-defined standards guide the implementation and use of these materials in construction projects. These guidelines ensure consistent quality and performance while providing clear frameworks for design and installation. The evolution of these standards reflects growing industry confidence and understanding of material capabilities.